Vol. 38 (Nº 33) Año 2017. Pág. 39

Nadezhda Konstantinovna SKVORTСOVA 1; Andrey Anatolievich MATYUKOV 2

Received: 11/06/2017 • Approved: 25/06/2017

ABSTRACT: When the country had moved to the market economy, the need in improving methodic basics of forming production program and managing the production capacity of enterprises emerged. These enterprises are based on the comprehensive approach, taking account such parameters as flexibility, adaptability, innovative orientation, and equation by production elements. The work aims at revealing groups of factors that have an impact on the process of stipulating the enterprise production capacity. In order to ground the research results, methods of logic, economic, and comparative analysis, and elements of system approach were used. The article considers problematic issues related to calculating the production capacity when forming the enterprise production program. They are related to considering methodological points that require finishing, clarifying and improving. Such points include terms and conditions of selecting the key link of production, clarifying the classification used in calculating the enterprise production capacity, stipulating the working time fund taken when making calculations, stipulation of measures used to estimate the production capacity, and specifying the succession of forming the enterprise production program. Today in spite of many years’ research practice, there is no rather grounded system approach to stipulating the production capacity within forming the enterprise production program. In this context, it is offered to transform the approach to forming the production program and stipulate the improvement of the methodology of calculating the production capacity based on using the indicator of the processing value added. |

RESUMEN: Cuando el país se había trasladado a la economía de mercado, surgió la necesidad de mejorar los fundamentos metódicos de la formación del programa de producción y la gestión de la capacidad de producción de las empresas. Estas empresas se basan en el enfoque integral, teniendo en cuenta parámetros como flexibilidad, adaptabilidad, orientación innovadora y ecuación por elementos de producción. El trabajo tiene como objetivo revelar grupos de factores que inciden en el proceso de estipulación de la capacidad productiva empresarial. Con el fin de fundamentar los resultados de la investigación, se utilizaron métodos de análisis lógico, económico y comparativo y elementos del sistema. En el artículo se consideran los problemas problemáticos relacionados con el cálculo de la capacidad de producción en la formación del programa de producción empresarial. Están relacionados con la consideración de puntos metodológicos que requieren acabado, clarificación y mejora. Dichos puntos comprenden los términos y condiciones para seleccionar el vínculo clave de la producción, aclarar la clasificación utilizada para calcular la capacidad de producción empresarial, estipular el fondo de tiempo de trabajo tomado en los cálculos, estipular las medidas utilizadas para estimar la capacidad de producción y especificar la sucesión de Formando el programa de producción de la empresa. Hoy en día, a pesar de la práctica de muchos años de investigación, no existe un enfoque de sistema más bien fundamentado para estipular la capacidad de producción dentro de la formación del programa de producción de la empresa. En este contexto, se propone transformar el enfoque de formación del programa de producción y estipular la mejora de la metodología de cálculo de la capacidad de producción basada en el uso del indicador del valor añadido de procesamiento. |

The activity of industrial enterprises in the context of modern market relations requires the implementation of new approaches when taking management decisions in production and selling final products. The novelty of approaches is stipulated by the need to provide the target and resourceful coordination of enterprises activity, to apply volume estimation indicators that comply with the market economy, to use progressive approaches to solving the whole complex of tasks the enterprise gets, and stipulating the economic efficiency of solving them.

To a great degree, the efficiency of the work of industrial enterprise depends on its production capacities and efficiency of using them. The modern enterprise functions in the context of physical torn and worn, and outmoded equipment (during the latest decades (1970-2015) the basic capital was updated mainly extensively; the moral tear and wear of basic funds is strengthened by the physical one; E.P. Pankratov in his work (Pankratov 2014) notes that by 2015 the size of the tear and wear of basic funds has been 64.4%), disproportions of production capacities that causes low return from exploiting them. Besides, there is growing competition, on the one hand, and decrease in investments in basic capital, on the other hand.

In this context, the basis of the enterprise production and economic activity efficiency is the formation of the rational production program (Karlik and Velikanov 1985; Samoylovich and Telushkina 2012). Its indicators take into account the change of the demand for products, their competitiveness and limited internal production opportunities of the enterprise.

In spite of the considerable development of theoretic and methodic basics of forming the production program, aspects of the system analysis as one of the main ways to describe it, there is almost no integral concept of forming the production program of an industrial enterprise.

Taking into account the current circumstances, the stipulation of the production capacity is a required organizational condition for developing the rational production program of the enterprise.

The research results are grounded on the basis of system use of general methods of logical, structural, functional and comparative analysis, theoretic modeling and statistical methods.

Problematic points of this issue were considered in detail. The initial components of the modern theory and methodology of forming the production program and calculating the basis of its forming – the production capacity – were defined.

As for the definition of the production program, it is possible to observe the entire solidarity since the previous century. Thus, for example, Velikanov K.M. in his work (Karlik, and Velikanov, et al. 1985) gives the following definition: “the production program is interpreted as the task on producing a specific amount of products of the set classification, range and quality”.

The enterprise production capacity is maximum possible annual production according to the classification and range provided by the plan subject to the entire use of the existing resources (Karlik, and Velikanov, et al. 1985; Skvortсova and Zenkina,. et al. 2011; Novashina and Karpunin 2014).

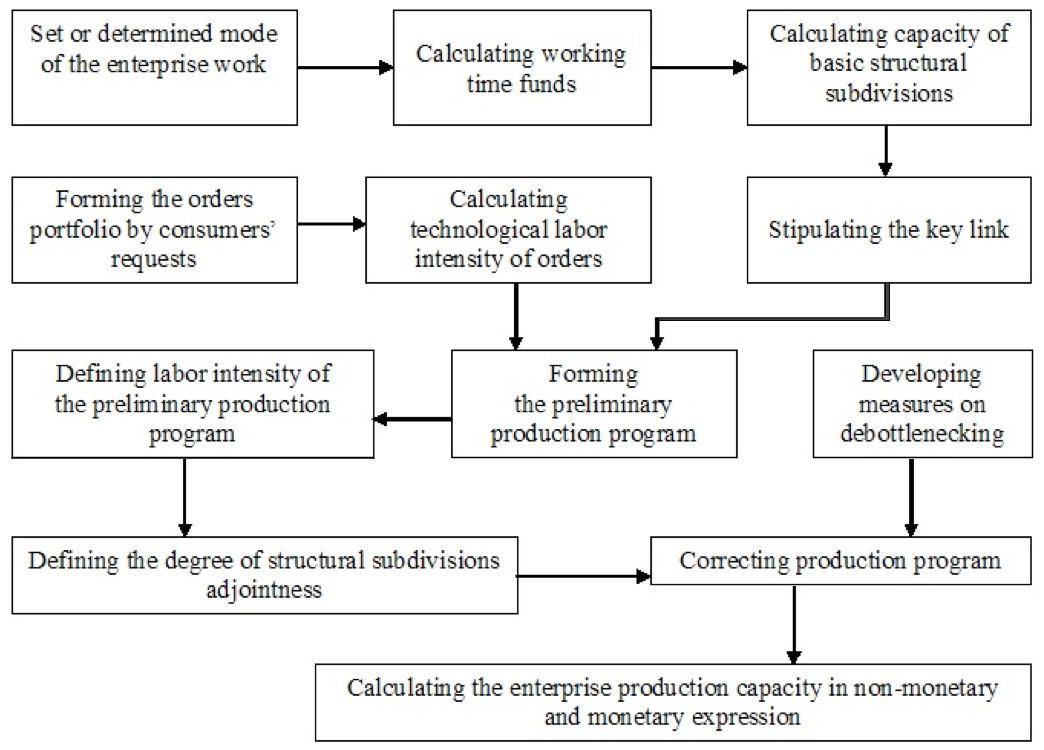

The production program is developed on the basis of studying the market by the marketing department and according to the scheme on Fig. 1 (Skvortсova and Zenkina et al. 2011; Avdeenko and Kotlov 1989).

Figure 1. Succession of Forming the Enterprise Production Program

Based on the conducted research of the theory and basic methods of forming the enterprise production program, it was determined that there was a number of issues requiring initial specifying in spite of a great number of methodologies and instructions on calculating production capacities of industrial enterprises (Akoff, 1985; Gruzinov 2009; Instruction on Calculating Production Capacities of Clothing Enterprises, 2003, etc.). Theoretic and methodic issues that have not been solved by now cause the situation when enterprises actually calculate the rate of throughput rather than the production capacity.

It is necessary to include issues related to selecting the accounted working time fund, measures of products, selecting the products classification for calculations in the number of methodically unsolved issues, and, what is the most important according to the authors, issues related to selecting the key link in production.

In accordance with the current methodologies of calculating the production capacity, the calculation is based on the principle of the key link in production. This production key link is interpreted as a unit (integral unit, group of equipment, production sector, section) where basic technological operations are made and that contains the greatest part of the production equipment (Karlik, and Velikanov, et al. 1985; Skvortсova, and Zenkina, et al. 2011; Novashina and Karpunin 2014).

As for selecting the production key link, theoretical materials that consider the production capacity do not give an unambiguous answer. The analyzed methodic developments recommend to use several production links. For example, enterprises producing plumbing piece parts and units are recommended to use three types of production: mechanical metalworking and production of separate items, assembling, welding of technical constructions and units, painting and completing of final products (Avdeenko and Kotlov 1989; Skvortсova and Zenkina, et al. 2011).

As for woodworking enterprises, depending on the nature of production (wood-sawing and planning, woodworking and mechanical, and combined), four types are recommended. Enterprises on producing metal and alloy constructions are recommended to use up to six types, etc.

The practice is the following. For example, as for enterprises producing metal constructions, the production capacity on them is defined by assembling. Herewith, it is suggested that the work of all adjacent links must entirely provide the work of the assembling subdivision. That is why the production capacity of mechanical processing subdivisions must be higher than that of assembling, and the production capacity of procuring subdivisions must be higher than that of mechanical processing.

Thus, this generated excessive production capacities of adjacent units that are under-used, as a rule.

The definition of the key link itself has a number of contradictions (Avdeenko and Kotlov 1989).

Firstly, it is possible to classify operations into basic and nonbasic rather conditionally because all technological operations are equally important for obtaining a high-quality product. Thus, based on the definition of the key link, it is possible to conclude that any stage of the technological process can be accepted as the basic one.

Secondly, under the use of modern technical achievements, the share of human labor decreases. Herewith, it happens mainly in basic production units, which are more paid attention to. Consequently, the areas where leading (basic) technological operations are made are not basic consumers of human labor at the same time.

As for the third component of the definition of the key link (focus of the basic part of production funds), it is necessary to note that the results of analyzing the structure of basic production funds (for example, enterprises on producing plumbing piece parts and units) say that the cost of funds of assembling structural subdivisions (that as a rule define the capacity of these subdivisions) is 1/20-1/10 of the total cost of the basic production funds of the enterprise (Bastrykin, 1983).. As compared to the mechanical processing units of production where expensive equipment is used, this value is not considerable.

Consequently, it is not objective to select the key link by this characteristic.

Thus, the use of the key link principle in calculating the enterprise production capacity causes the situation when all other production sectors are underloaded. It results in forming the reserves of the production capacity that are not used for calculating the products issue.

In this context, it is impossible to say that the production capacity characterizes the maximum possible annual production by the enterprise as it goes from the definition.

The second disputable methodic issue is related to the classification used for calculating the production capacity: planned (suggested) or optimal.

If calculations are made by using the planned classification, in the context of the modern instability of the market economy it is not possible to form the grounded production program per year.

Besides, in this case the basis for calculating the production capacity is the production program, and not the other way round. This is the production capacity that is the basis of forming the plan of production.

Some authors think that it is necessary to measure the production capacity in the optimal range of products (Gruzinov 2009; Bastrykin, 1983). It is stipulated by the fact that in this case every unit of equipment is loaded to its maximum, which contributes to obtaining the best results of the enterprise activity.

The third offered variant of calculating the production capacity is the calculation in the classification that complies with the specialization of the structural subdivision under consideration (Avdeenko and Kotlov 1989), Methodological Guide to Developing Plans of Economic and Social Development of the RSFSR, 1985).

The above says that every variant assumes the use of the limited range of products.

It is possible to practically use such methodologies in the limited number of productions that make a limited number of products.

The modern practice of industrial enterprises’ activity shows that more and more types of products are made in a one-of-a-kind or low-volume mode under the relevant expansion of the classification. That is why the calculations are made according to the calculation program by the representative items, i.e. by using its conditionally non-monetary measures (Zaytsev 2008; Smolyanova 2011).

There is the third disputable methodic issue: how to apply products measures when calculating the enterprise production capacity.

Most often, it is recommended to make calculations by using non-monetary and monetary measures.

However, the use of monetary measures (trade prices) causes subjective estimation of the production capacity, because the monetary estimation depends on the materials/output ratio, prices for materials, etc. that do not reflect efforts of the producer himself.

The use of non-material units of measuring is directly related to selecting the production program, and consequently the classification of products. Inter alia, as it has been stated above, this issue has not been unambiguously solved by this time, and its practical implementation is complicated.

As a rule, it is recommended to be based on the program approved for the target year allowing to apply two types of classification: planned (in case of defining the production capacity to define the planned volume of production) and optimal (in case of pre-plan calculations) (Novashina and Karpunin 2014; Smolyanova 2011).

When using conditionally non-monetary measures, the production capacity rather considerably depends on the range shift and the representative product used for calculating.

The variety of types of products causes specific difficulties when applying non-monetary indicators and opportunities to give the generalized estimate to the production capacity in the unified measures.

The problem of selecting the average classification when calculating the production capacity is estimated by all researchers as rather difficult. Therefore, there is practical difficulty in estimating real production capacities.

Besides, as it has already been stated, when using monetary (conditionally monetary) measures in estimating the production capacity, unused reserves of the production capacity occur almost for all production operations as a result of repeated correlation between the labor intensity of operations related to the representative item and the capacity of working places.

Consequently, the use of non-monetary measures does not make it possible to reveal the real production capacity of the enterprise.

The total production capacity of the enterprise considered as an aggregated system and measured in non-monetary units can be defined only if this system makes only one product.

The scheme shown on Fig. 1 shows that firstly the production program is formed, and the production capacity is calculated only at the final stages. Consequently, the possibility to define the production capacity is included before the production program is formed. Such state of the matter is not adequate.

And, finally, the fourth disputable moment of the existing theory and practice of calculating the enterprise production capacity is related to using the fund of working time of equipment.

If calculations are made by using the planned fund of time, in this case the quotient of using the production capacity can exceed “1” (because the work is possible on days off, the time spent for repairing equipment decreases) which contradicts to the definition of the production capacity that defines the production capacity as the maximum possible production.

If the calendar fund of working time is taken into account, the level of using production capacity will be very low at enterprises with continuous technological process. However, herewith, the real loading of equipment does not decrease, and the indicator of using the production capacity will show the real situation with the reserves.

In spite of the many years’ research practice, the issues of theory and methodology of planning that have not been solved by now cause the situation when the capacity of enterprises is calculated rather than the production capacity.

Based on the above problems related to forming the enterprise production program, a number of approaches to estimating the enterprise production capacity when forming the production program were considered. It has been revealed that the current methodologies of calculating and the adopted scheme of forming the production program cause the situation when there is no any opportunity to determine the production capacity until the production program is formed. In order to eliminate the revealed disadvantage of the current approaches, it is offered to change the calculation scheme of forming the enterprise production capacity where calculations of the production capacity must dominate. They include defining the production capacity of working places and the number of producing working places, then calculating the enterprise production capacity, and at the final stage, forming the enterprise production program.

Besides, the issue related to selecting measures of products measurement when calculating the enterprise production capacity requires methodic completion, because the use of most often recommended monetary and non-monetary measures causes a subjective estimate of the production capacity in the first case due to their dependence on the materials/output ratio, and due to the fact that their use is directly related to selecting the classification of the products. This issue has not been clearly solved up to now.

In the context of modern production when working places turn into orderly organized and managed initial cells of production, it is reasonable to improve the methodologies of calculating the production capacity focused particularly on using the indicator of the value added of processing (net product, regulatory net product) produced per hour at the working place as a measure of the production capacity.

Akoff, R. JI. (1985). Planirovanie buduschego korporatsii [Planning the Corporation Future]. Moscow: Progress, pp. 326.

Avdeenko, V.N. and Kotlov, V.A. (1989). Proizvodstvenniy potentsial promyshlennogo predpriyatiya [Production Potential of the Industrial Enterprise]. Moscow: Ekonomika, pp. 240.

Bastrykin, A.N. (1983). Predpriyatie promyshlennyih predpriyatiy stroitelnoy industrii [Enterprise of Industrial Construction Companies]. Moscow: High School, pp. 240.

Gruzinov, V.P. (2009). Opredelenie optimalnogo obioma proizvodstva produktsii [Defining Optimal Volume of Production]. Industrial Marketing, 2, 77 – 79

Instruktsiya po raschetu proizvodstvennyh moschnostey predpriyatiy shveynoy promyshlennosti (krupnyh, srednih i malogo biznesa) v usloviyah rynochnoy ekonomiki [Instruction on Calculating Production Capacities of Clothing Enterprises (Large, Medium and Small-Sized) Under Market Economy]. 11.06.2003.

Karlik, E.M. and Velikanov, K.M., et al. (1985). Ekonomika mashinostroeniya [Economy of Machine-Building]. Leningrad: Machine Building, pp. 392.

Metodicheskie ukazaniya k razrabotke planov ekonomichekogo I sotsialnogo razvitiya RSFSR [Methodological Guide to Developing Plans of Economic and Social Development of the RSFSR]. (1985). Moscow: Economy, pp. 456.

Novashina, T.S. and Karpunin, V.I. (2014). Ekonomika i finansy predpriyatiya [Enterprise Economy and Finances]. Moscow: Synergy, pp. 352.

Olhovaya, M.V. and Shinkevich, A.N. (2006). Sovremennye metodiki planirovaniya proizvodstvennoy programmy predpriyatiy shveynoy promyshlennosti [Modern Methodologies of Planning Production Program of Clothing Enterprises]. Modern Tendencies of Developing the Russian Economy. Krasnodar: Publishing House of KubGTU

Pankratov, E.P. (2014). Pankratov, O.E. Ob inostrannyh investitsiyah, perspektivnyh napravleniyah ispolzovaniya v stroitelstve i prichinah, sderzhivayuschih ih postuplenie [About Foreign Investments, Perspective Areas of Using in Construction and Reasons Restraining Their Receipt]. Construction Economy, 1, 3 – 11.

Samoylovich, V.G. and Telushkina, E.K. (2012). Ekonomika predpriyatiya [Enterprise Economy]. Moscow: Academia, pp. 224.

Skvortсova, N.K. and Zenkina, M.V. et al. (2011). Ekonomika i organizatsiya proizvodstva na predpriyatiyah otrasli [Economy and Organization of Construction at Sectoral Enterprises]. Tyumen: RIO TyumGASU, pp. 232.

Smolyanova, E. L. (2011). Algoritm formirovaniya i realizatsii strategii innovatsionnogo razvitiya predpriyatiya [Algorithm of Forming and Implementing the Strategy of Innovational Development of the Enterprise]. Economy and Entrepreneurship, 5 (22), 110-114

Zaytsev, H.J. (2008). Ekonomika, organizatsiya i upravlenie predpriyatiem [Economy, Organization and Management of Enterprise]. Moscow: Infra-M, pp. 455.

1. Federal State Budget Educational Institution of Higher Education “Industrial University of Tyumen”, 625000, Russian Federation, Tyumen, Volodarsky St., 38

2. Federal State Budget Educational Institution of Higher Education “Industrial University of Tyumen”, 625000, Russian Federation, Tyumen, Volodarsky St., 38